Top 7 Best Brake Pad Manufacturers in 2026 | Buyer’s Guide

Explore the top 7 brake pad manufacturers in 2026. Compare performance, durability, materials, and OEM options to find the best supplier for your braking needs.

What to Look for in the Best Brake Pad Manufacturers

When I’m evaluating the best brake pad manufacturers, I treat the process a bit like interviewing a team of engineers for a high-stakes mission, because, frankly, your brakes are a high-stakes mission.

Whether I’m sourcing from global brake pads wholesale suppliers or comparing brands for performance-focused drivers, I always look deeper than glossy catalogs or nice-looking product photos.

I want proof, engineering logic, and a level of consistency that feels as reliable as flipping on a light switch, you expect it to work every single time.

Below are the key things I personally inspect when determining whether a manufacturer is truly worth trusting.

Material Technology and Safety Standards

Whenever I talk to a manufacturer, the first thing I look at is their material science. Brake pads are basically friction engineering in action, and the material formula determines everything, performance, heat resistance, noise, durability, and safety.

The best manufacturers invest heavily in R&D, often developing proprietary formulas like:

- Semi-metallic blends for high stopping power

- Ceramic compounds for quieter and cleaner braking

- Low-metallic NAO for balanced street performance

- Sintered metal pads for heavy-duty vehicles and disc brakes for bikes

To me, if a manufacturer can’t clearly explain their friction material composition and why it performs better, that’s a red flag. The top companies treat friction formulas like Michelin treats its rubber compounds: strictly engineered and tested, not guessed.

Types of Brake Pads: Which One Fits Your Vehicle?

When I choose brake pads, whether I am reviewing global brake pad manufacturers or comparing products from major brake pads wholesale suppliers, I treat the process like picking the right pair of shoes for the right situation.

You would not wear hiking boots to run a marathon, and you would not wear running shoes to a construction site. Brake pads work the same way. Each type has a unique personality, a specific strength, and a recommended driving environment.

Below is the breakdown I usually share with drivers, mechanics, and distributors. Choosing the correct type can completely change your braking experience and make your vehicle feel safer, smoother, and more predictable.

Ceramic Brake Pads

Ceramic brake pads are the quiet and reliable type that simply get the job done without drawing attention. They are a favorite among many brake pad manufacturers because they offer a strong balance of comfort and long-term performance.

What I appreciate about ceramic pads:

- Very quiet operation

- Low dust and cleaner wheels

- Smooth and consistent braking

- Long lifespan with stable friction

- Good compatibility with most driving environments

Ceramic pads are perfect for daily commuting, family vehicles, and premium sedans. They are available for some disc brakes for bikes as well, especially higher-end models focused on quiet performance and smooth modulation.

Semi-Metallic Brake Pads

If ceramic pads are the quiet professionals, semi-metallic brake pads feel more like seasoned athletes who thrive under pressure. They are designed to handle demanding driving conditions and higher heat levels.

Key advantages include:

- Excellent heat dissipation

- Strong stopping power under heavy load

- High durability

- Better performance for towing and spirited driving

These pads tend to be slightly noisier compared to ceramic pads, and they produce more dust. However, for trucks, performance cars, or any vehicle that faces higher braking stress, semi-metallic pads are often the smartest choice. Many brake pads wholesale suppliers list semi-metallic pads as top sellers because they suit a wide range of vehicle types.

Low-Metallic NAO Brake Pads

Low-metallic NAO pads sit right in the middle. I often describe them as hybrid shoes that combine comfort with durability. They include a modest amount of metal to increase friction strength without going full semi-metallic.

Their typical benefits:

- Stronger bite compared to ceramic pads

- Better heat resistance than organic pads

- A good balance between performance and comfort

They do create more dust and noise than ceramic pads, but they are a very practical option for highway drivers or anyone who needs reliable stopping without extreme performance demands. For disc brakes for bikes, low-metallic NAO compounds are becoming more popular because they offer solid braking under long downhill rides.

Organic Brake Pads (Non-Asbestos)

Organic pads, often labeled NAO, are the comfortable everyday sneakers of the brake pad world. They are soft, quiet, and affordable, which makes them a great option for lighter vehicles and short-distance driving.

Common materials include:

- Kevlar fibers

- Glass fibers

- Rubber compounds

- Resin-based binders

Why people choose organic pads:

- Very quiet operation

- Soft pedal feel

- Low rotor wear

- Lower cost compared to other types

These pads do wear out faster and lose efficiency under very high heat. They are common in many entry-level disc brakes for bikes because they offer a smooth and predictable stopping feel without extra weight or aggressive friction.

High-Performance Brake Pads for Racing and Heavy-Duty Use

High-performance brake pads are designed for extreme situations such as racing, drifting, aggressive mountain driving, or heavy-duty towing. This category is the sports gear of brake pads. They are built for peak performance, not for everyday comfort.

Typical advantages:

- Very high thermal resistance

- Strong initial bite

- Fade-free braking even under repeated hard stops

- Precise and consistent pedal feel

There are some trade-offs:

- Higher noise

- More brake dust

- Faster rotor wear

- Not ideal for casual city driving

Most high-end brake pad manufacturers produce specialized racing or heavy-duty lines. These pads are also popular with premium brake pads wholesale suppliers because performance drivers and mechanics demand products that can survive extreme temperatures and harsh conditions.

Top 7 Best Brake Pad Manufacturers in 2026

Key comparison points for these brake manufacturers

- Product scope and system completeness

- Brake technologies offered

- Target bikes and applications

- Performance and braking feel

- Heat management and durability

- Safety standards, testing and quality control

- OEM strength and key bike brand customers

- Aftermarket presence and serviceability

- Price and positioning

- Innovation and product updates

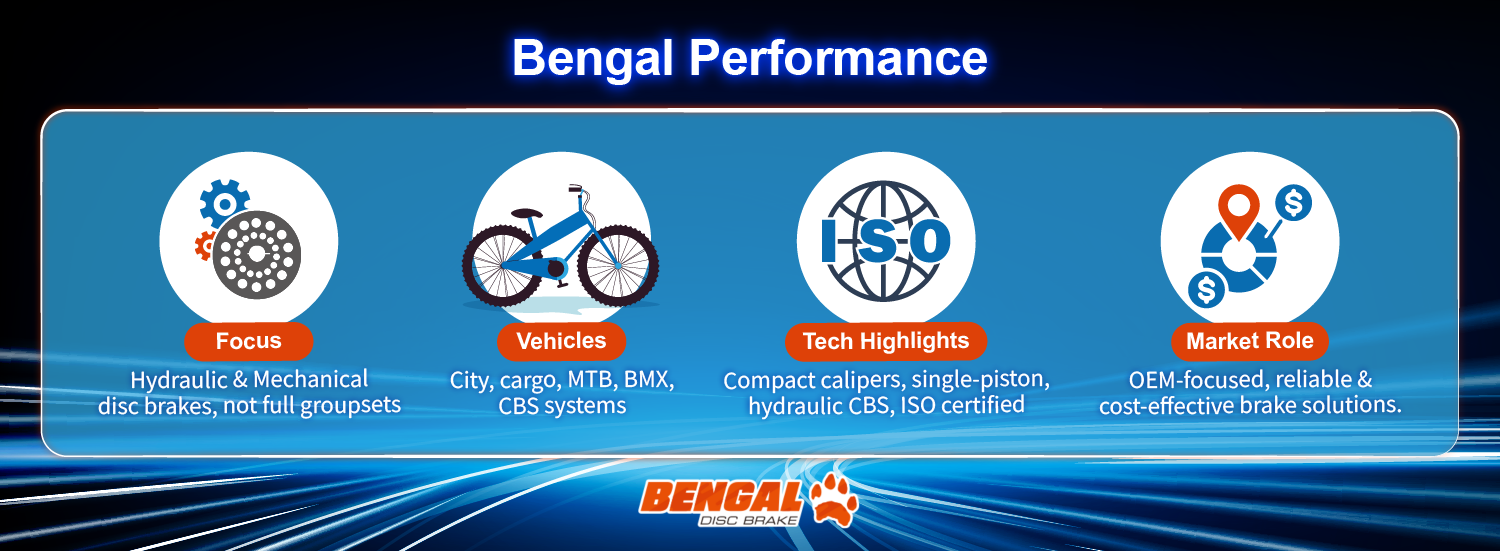

Bengal Performance

Bengal is a Taiwan based brake specialist that focuses on bicycle disc brake systems rather than full groupsets. The company highlights hydraulic disc brakes, mechanical disc brakes and supporting parts such as rotors, adapters and center lock adapters as its core business.

Its product navigation clearly separates brake systems from components and then ties them to real world use cases. Bengal lists applications for cargo bikes and trikes, city and urban bikes, MTB, BMX racing and a combined braking system (CBS) for front and rear integration, which is especially relevant for cargo and utility bikes.

On the technology side, Bengal promotes compact forged calipers, single piston mechanical designs, and hydraulic CBS systems that distribute braking force between front and rear wheels in order to shorten stopping distance and improve stability. The company also points out compliance with ISO standards and braking performance approval according to DIN and CEN norms, supported by quality controls such as IQC, IPQC and OQC for OEM customers.

Role in the market:

Bengal is best viewed as an OEM oriented disc brake supplier that offers complete brake solutions for brands that need reliable and cost effective systems for city, cargo, trekking and off road bikes rather than a full drivetrain package.

Shimano

Shimano is the largest bicycle component supplier in the world and is especially dominant on OEM spec for complete bikes. For brakes, Shimano offers a very wide catalogue that includes hydraulic disc brakes, mechanical disc brakes, rim brakes, V-brakes, roller brakes, rotors, brake levers and small parts.

On the performance side, Shimano promotes strong braking power, heat management and reliability across road, gravel and mountain biking. Hydraulic disc brake systems are integrated into road groups like Dura-Ace, Ultegra and 105, as well as MTB and e-bike lines. The brand also provides very complete documentation and spare parts availability, which makes it easy for mechanics and shops to service the brakes.

Role in the market:

Shimano combines huge OEM share, full system integration and strong global service. For a bike brand that wants a turnkey solution from entry level up to pro racing level, Shimano is often the default reference.

SRAM

SRAM is a US based component brand that competes directly with Shimano at the mid to high end of the market. It offers brakes as part of a complete ecosystem that includes drivetrains, cranksets, cassettes, chains and more. In the brake segment, SRAM lists disc brakes, rotors, mechanical brake levers and brake accessories for both road and mountain applications.

SRAM’s marketing focuses on braking power, consistency and modulation, especially for aggressive riding. MTB families such as Code and G2 target downhill, enduro and trail riders, while road and gravel brakes are integrated into wireless AXS groupsets like Red, Force, Rival and Apex. SRAM also provides detailed guides for choosing replacement brake pads, which is important for long term service and performance tuning.

Role in the market:

SRAM is a high performance choice, especially for riders and brands that want wireless drivetrains and powerful, modern hydraulic disc brakes on performance focused road, gravel and MTB platforms.

TRP Cycling

TRP is the performance oriented brand within the Tektro group. It focuses on high performance brakes and drivetrains for demanding applications. The TRP brakes category shows hydraulic and mechanical disc brakes for MTB, gravel and road, along with pads, rotors, adapters, levers and small parts.

TRP states that its brakes deliver precision, power and control in all conditions. Product lines such as EVO PRO are designed for serious downhill, enduro, trail and e-MTB riders, and TRP describes close collaboration with World Cup downhill athletes in the development process. This confirms the brand’s focus on race ready performance and tuning.

Role in the market:

TRP targets mid to high end bikes where performance and feel matter more than minimum cost. It is a good match for brands that want something more niche and race focused than mainstream OEM brakes, especially in gravity and aggressive trail segments.

Magura

Magura is a German brand known for both bicycle and motorcycle components. In the bicycle area, Magura produces disc brakes, rim brakes and original spare parts such as rotors, pads, adapters and mineral oil for all major cycling disciplines.

Magura’s MTB brake lineup is supported by many World Championship titles and test wins, which the company highlights on its MTB pages. The brand emphasizes braking power and optimal performance, and its organic pad compounds are tuned to work with Magura calipers and rotors for consistent braking and good heat management.

Role in the market:

Magura tends to be chosen for high end MTB, gravity and e-MTB where riders and brands want strong performance with a “German engineering” image. It also benefits from being part of a broader powersports ecosystem.

Hayes Bicycle (Hayes Performance Systems)

Hayes Bicycle is part of Hayes Performance Systems, which describes itself as a global manufacturer of brakes, suspension systems, wheels and components. The bicycle side includes Hayes brakes, Manitou suspension, Reynolds wheels, SunRinglé wheels and ProTaper components.

On the dedicated brakes site, Hayes presents itself as having “the most reliable and performance oriented brakes and brake rotors” for mountain biking. The company notes that it has decades of brake production experience outside of cycling and that it played a key role in bringing hydraulic disc brakes into the MTB world, which gives it strong credibility in brake engineering.

Role in the market:

Hayes is a strong option for brands and riders who care about long descents, tough riding conditions and integrated ecosystems that include suspension and wheels. It is especially relevant in trail, enduro and downhill categories.

Formula SRL

Formula SRL, marketed under the RideFormula brand, is an Italian company with a long history in high performance braking. According to its own heritage story, Formula created what is considered the first hydraulic disc brake dedicated to mountain biking in 1993, which marked a turning point in MTB brake technology.

Since then, Formula has focused on high end brakes and suspension for mountain bikes. Catalogs and brand stories describe a continuous focus on top quality wheels and brakes, with an emphasis on performance for demanding riders. Modern product lines include powerful disc brakes and suspension forks aimed at trail, enduro and downhill bikes.

Role in the market:

Formula is positioned as a premium, performance driven Italian brand with strong historical credibility in MTB disc brakes. It is attractive for brands and riders that want a distinctive European image and race proven performance rather than a mass market solution.

The Complete List: TOP 7 Brake Pad Manufacturers

- Bengal(https://www.bengalperformance.com.tw/)

- SHIMANO(https://bike.shimano.com/)

- SRAM(https://www.sram.com/)

- TRP Cycling(https://trpcycling.com/)

- MAGURA(https://magura.com/)

- Hayes Bicycle(https://hayesbicycle.com/)

- Formula SRL(https://www.rideformula.com)

How to Choose the Right Brake Pad Brand for Your Driving Needs

Whenever I help someone pick the right brake pad brand, I always compare the process to choosing the right gear for a road trip.

The journey matters as much as the destination, and your driving habits shape what type of braking setup you truly need.

The best brake pad manufacturers design products for very different situations, so selecting the right one can improve safety, braking comfort, and even long-term maintenance costs.

Below are the criteria I personally use when deciding which brake pad brand fits a specific driving lifestyle.

For Daily Commuting

For everyday driving, I prefer brake pads that feel smooth, quiet, and reliable. Most commuters want a comfortable ride without excessive brake dust or harsh pedal feedback.

Here is what I usually recommend:

- Ceramic brake pads

- Low dust and quieter operation

- Gentle rotor contact for longer service life

- Stable performance in stop-and-go traffic

Most reputable brake pad manufacturers offer ceramic options designed specifically for city driving. For cycling commuters using disc brakes for bikes, ceramic or organic pads work well because they provide predictable stopping at low speeds.

For Heavy-Duty Trucks and SUVs

When I choose brake pads for trucks or SUVs, I look for strength and durability. Vehicles that tow, haul, or drive on steep terrain need pads that can survive higher heat levels and heavier loads.

The best choices usually include:

- Semi-metallic brake pads

- High thermal resistance

- Stronger braking force under load

- Better performance during long downhill drives

Many brake pads wholesale suppliers stock heavy-duty lines because commercial and utility drivers demand tougher friction materials. For these vehicles, the right brand can make a noticeable difference in braking confidence.

For High-Performance or Racing

Performance driving is a different world. The braking system has to handle repeated hard stops, high temperatures, and rapid deceleration. When I choose pads for racing or performance builds, I look for aggressive friction formulas that maintain grip even under extreme heat.

Ideal characteristics include:

- High-performance semi-metallic or carbon-ceramic pads

- Consistent friction during repeated braking

- Extremely high heat tolerance

- Strong initial bite for track conditions

Many high-end brake pad manufacturers produce specialized racing lines because enthusiasts want products that deliver precision control at high speeds.

These pads are popular among advanced drivers and racing teams who regularly purchase through specialized brake pads wholesale suppliers.

For EV and Hybrid Vehicles

Electric vehicles and hybrids behave differently during braking because regenerative braking handles part of the stopping process. This means the friction brakes engage less frequently but require materials that resist corrosion and remain reliable after long intervals of minimal use.

My preferred choices for EVs include:

- Ceramic pads with noise-reduction features

- Low-dust formulations to protect sensitive components

- Pads designed to resist moisture and rust

- Stable performance even after long periods of light use

Some modern brake pad manufacturers are developing EV-specific friction formulas. These pads provide a smoother pedal feel and reduced noise, which fits the quiet nature of electric vehicles.

For Budget-Friendly Replacement Options

When someone needs an affordable replacement, I do not automatically recommend the cheapest option. Instead, I look for brands that offer reliable quality at a reasonable price. A low-cost pad that wears out quickly is not truly budget-friendly.

Good budget-level choices often include:

- Organic or standard ceramic pads

- Reliable performance for everyday driving

- Lower upfront cost

- Adequate lifespan without rapid decline

Many brake pads wholesale suppliers carry budget lines from reputable manufacturers, giving drivers accessible options without sacrificing safety.

Budget-friendly pads are also popular for entry-level disc brakes for bikes, where riders want a decent stopping response without paying for premium racing compounds.

Signs You Need to Replace Your Brake Pads

Whenever I am inspecting a braking system, I always tell people that brake pads communicate long before they completely fail.

They drop hints, just like an old pair of shoes that starts to squeak or lose grip. If you recognize the early signs, you can avoid expensive repairs and keep your brakes performing the way brake pad manufacturers originally intended.

Here are the warning indicators I pay close attention to, whether I am checking a car, a truck, or even disc brakes for bikes.

Squeaking, Grinding, and Vibration

The first sign I usually notice is noise. Brake pads that are nearing the end of their life often make squeaking or screeching sounds. Many pads have built-in wear indicators that purposely create noise when the pad material gets thin. This sound is like a gentle reminder that it is time to schedule maintenance.

Grinding noises are a more serious issue. When I hear grinding, it usually means the pad material is fully worn down and the metal backing plate is scraping against the rotor.

This can cause costly rotor damage. Vibrations or pulsing in the brake pedal can also indicate worn pads, warped rotors, or improperly seated friction material.

Both major brake pad manufacturers and brake pads wholesale suppliers often highlight these symptoms in their product manuals, and for good reason. They should not be ignored.

Longer Stopping Distance

If your vehicle starts needing extra space to slow down, that is a red flag. Brake pads lose efficiency as they wear, and you may feel the pedal getting softer or requiring more pressure.

I always test braking responses in a safe, open area. If I need noticeably more road to stop the vehicle, it is a clear sign that the pads have reached the end of their usable life. For disc brakes for bikes, riders often feel this as reduced bite or a mushy lever feel.

Changes in stopping distance can be subtle, which is why regular inspections matter. A fresh set of pads can restore braking power and make the entire system feel more responsive.

Dashboard Brake Warning Light

Many modern vehicles include a brake wear sensor. If the dashboard brake warning light turns on, I treat it as a direct message from the car that the pads need attention. It might not always mean immediate danger, but it always calls for a prompt inspection.

Brake pad manufacturers design these systems to activate at a specific wear threshold. Ignoring the warning light can lead to rotor damage, reduced braking safety, and higher repair costs.

For fleet managers or buyers working with brake pads wholesale suppliers, this reminder system is especially important because it reduces downtime and helps prevent unexpected maintenance issues.

Uneven Wear or Visible Pad Damage

When I visually inspect brake pads, I look for uneven wear, cracks, glazing, or chunks missing from the friction material. These issues can happen for several reasons, including:

- Caliper malfunction

- Misaligned hardware

- Overheating during heavy braking

- Low-quality pad material

- Contaminants on the rotor or pad surface

Uneven wear often signals a mechanical issue that needs repair in addition to replacing the pads. Even disc brakes for bikes can show similar patterns when the caliper alignment drifts or when pads overheat on long downhill rides.

A clean, evenly worn brake pad tells me that the braking system is healthy. Any visible damage tells me it is time for a replacement.

FAQ: Popular Questions About Brake Pad Brands

Which brake pad manufacturer is the most reliable?

From my experience, the most reliable brake pad manufacturers in 2026 are the ones that combine strong quality control with proven certifications such as ISO and ECE R90. Reliability comes from consistent materials, stable friction performance, and transparent testing data.

I always prefer brands that invest in research and maintain long-term relationships with global distributors. Companies with a strong presence among major brake pads wholesale suppliers usually have better product stability because they produce large batches with strict quality oversight.

The most reliable manufacturer for you depends on your vehicle type, your driving habits, and your budget.

Are ceramic brake pads better than semi-metallic?

Ceramic and semi-metallic pads are both excellent, but they are designed for different situations. Here is how I explain it:

Ceramic pads are ideal for drivers who want quiet braking, low dust, and smooth performance. They are great for daily commuting, city driving, small to mid-size vehicles, and even some disc brakes for bikes designed for quiet operation.

Semi-metallic pads are better for drivers who need stronger heat resistance and higher braking power, such as trucks, SUVs, performance cars, or anyone who tows heavy loads.

Neither type is universally better. The right choice depends on how hard you push your brakes.

How long do premium brake pads typically last?

Premium brake pads usually last between 30,000 and 70,000 miles, depending on:

- Driving style

- Road conditions

- Vehicle weight

- Material type

- Rotor condition

Ceramic pads tend to last longer in city driving because they handle heat more gently. Semi-metallic pads may wear faster if they are used aggressively or in mountainous areas.

For riders using disc brakes for bikes, lifespans are typically shorter because pad material is thinner and exposed to the environment. Weather, terrain, and braking frequency all affect durability.

High-quality brake pad manufacturers usually provide estimated mileage ranges based on controlled testing.

Is it safe to buy aftermarket brake pads online?

Yes, it is safe to buy aftermarket brake pads online if you follow a few smart steps. Here is what I always check before ordering:

- Does the brand come from a reputable manufacturer

- Are product reviews consistent and detailed

- Does the seller provide clear specifications

- Are certifications such as ECE R90 or ISO listed

- Is the warranty easy to understand

There are many reliable aftermarket brands sold through brake pads wholesale suppliers and authorized resellers. The key is to avoid unknown sellers who do not list technical details or certification information.

Buying online can save a lot of time and money as long as you verify that the pads match your vehicle model.

How do I pick the right brake pad for my car model?

Choosing the right brake pad always starts with your vehicle’s specifications. Here is the process I use:

- Check the exact model, year, and trim

- Look at rotor type and caliper design

- Review driving habits and usual load conditions

- Determine whether you need ceramic, semi-metallic, or organic

- Confirm size and shape using the manufacturer’s part number

The safest approach is to select pads recommended by reputable brake pad manufacturers or trusted wholesale suppliers. Many online catalogs allow you to search by vehicle model to ensure a perfect fit.

For disc brakes for bikes, the process is similar. You must match the caliper system and rotor size to ensure proper alignment and stopping power.

Still deciding which brake pad manufacturer to partner with?

Bengal Performance Brake Systems is a Taiwan-based manufacturer specializing in bicycle brake systems. The company focuses on designing and producing hydraulic and mechanical disc brakes, along with rotors, adaptors, and related components.

Bengal is known for stable quality, strict ISO-based quality control, and reliable OEM / ODM capabilities. Their brake systems are suitable for MTB, city bikes, BMX, cargo bikes, and various riding environments.

With continuous innovation and durable designs, Bengal aims to provide safe, dependable, and high-performance braking solutions for global bicycle brands.

If you have any brake pad purchasing needs, feel free to contact us, we’d be happy to discuss your requirements in detail.

Contact us:https://bengalbrake.com/